The SWISS COMBI belt dryer utilizes waste heat, making it an excellent fit for the current era of intelligent energy utilization. With over 200 installations worldwide, this drying technology satisfies our customers daily.

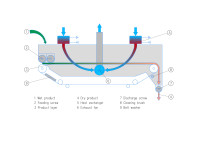

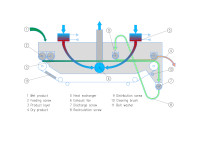

Our belt dryer, also known as a Low-Temperature Dryer (LTD), gently dries your product using hot air. Waste heat in the form of hot water, condensate, or saturated steam serves as the heat source, heating the ambient air up to 110°C. Depending on the product requirements, the drying process reduces the moisture content of the product to a range of 40% to 2%.

The SWISS COMBI belt dryer is suitable for organic bulk materials that are permeable to air and have low odor. It features a modular design, low emission values, low power consumption, and low maintenance costs.

Depending on the desired moisture content of the dried product, a single-layer or a double-layer belt dryer is employed. For products with a required moisture content higher than 20% after drying, a single-layer belt dryer is suitable. If the residual moisture needs to be below 20%, a double-layer dryer is ideal.

Depending on the available space, multiple units can be built above or beside each other.